Our Valued Customers

We proudly serve these industry leaders

Seshasayee Paper and Boards Ltd

Manufacturer Industry

URC

Construction Industry

Christy

Foods Industry

Auro Labs

Medical Devices Industry

Alzest Auto Cast

Manufacturing Industry

Vijay Tool Room

Tool Room Engineering Industry

Precision Manufacturing Excellence

MGT Industries is a leading provider of precision CNC solutions. With skilled experience and state-of-the-art technology, we specialize in delivering high-quality, Accuracy, and Reliability machined components tailored to your specifications. We cater to industries that demand complex, precision, efficiency and excellence.

Our commitment to quality, innovation, and customer satisfaction drives us to exceed expectations in every project. Whether it's small-batch prototypes or large-scale production, we ensure superior craftsmanship, tight tolerances, and timely delivery.

Partner with us for precision-engineered solutions that power your success!

Comprehensive CNC Solutions

At MGT, we offer a comprehensive range of precision machining solutions to meet the diverse needs of our clients. With advanced technology and expert craftsmanship, we ensure high-quality manufacturing and reliability.

Production Facilities

- Dedicated manufacturing space spanning 5400 Square Feet, optimized for CNC operations

- Layout designed for efficient material flow and reduced downtime

Machining Centre

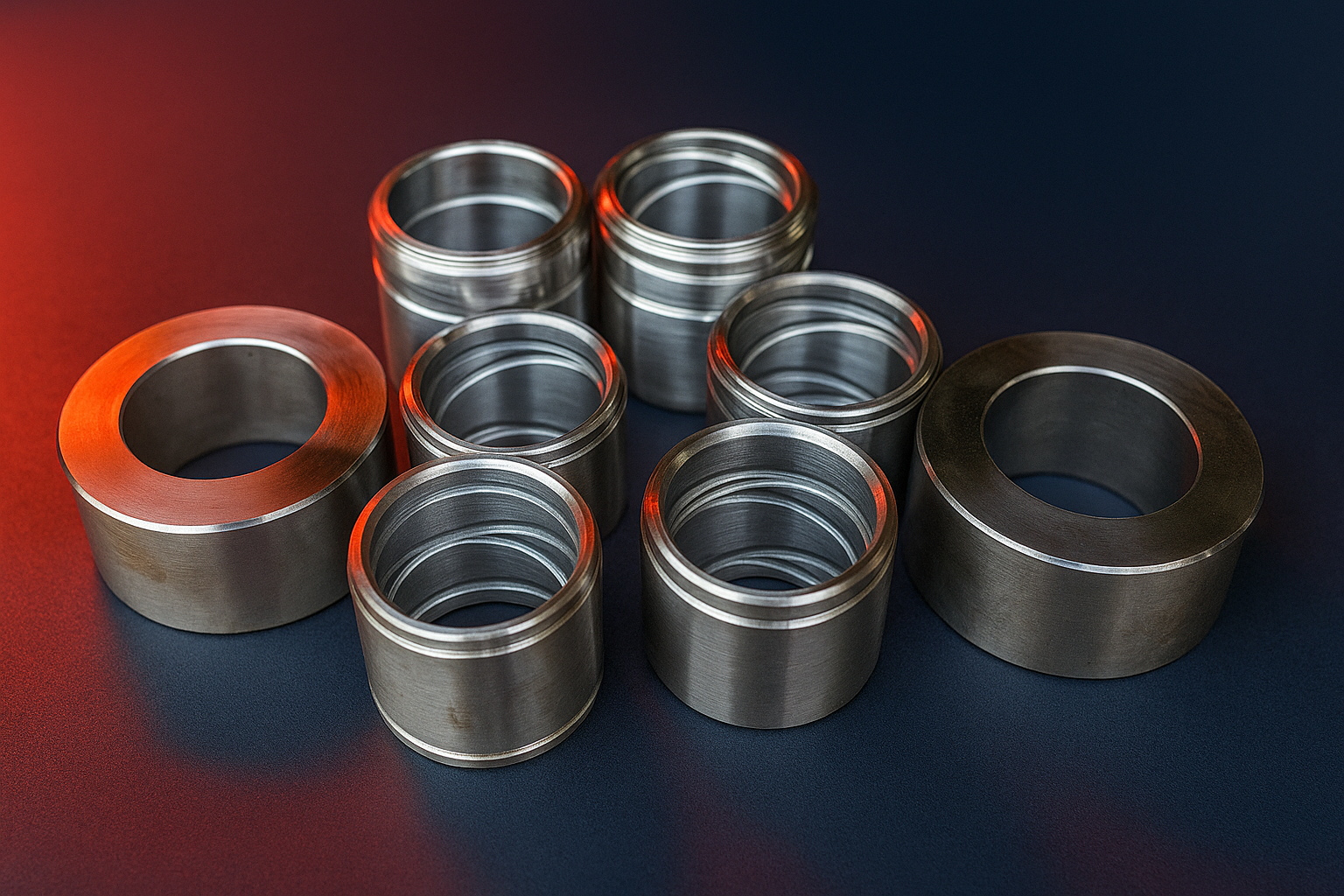

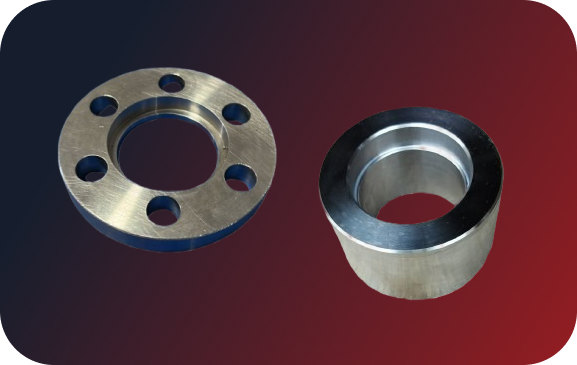

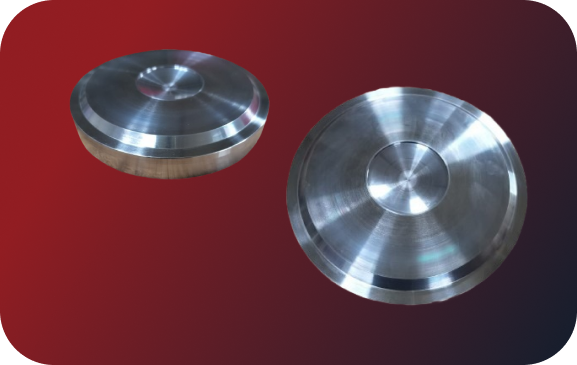

- CNC Turning – High-precision turned components with tight tolerances and superior finishes

- Turning capacity Ø350x450mm

- Mill cum Drilling – X800, Y400, Z350mm

- Cutting machine – Semi automatic – Ø400mm Max

- CNC Turning – Make : ACE Microsmatic – Model: 2025

- Cutting Machine – Make: Bhavya – Model: 2025

- Mill Cum Drilling Machine – Make: Jay Ind. – Model - 2025

Tooling & Design

- Custom Fixtures – Designed to enhance manufacturing accuracy and efficiency

- Jigs & Gauges – Precision-engineered for quality control and consistency

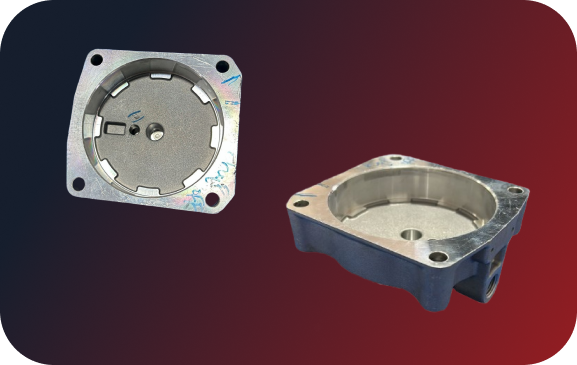

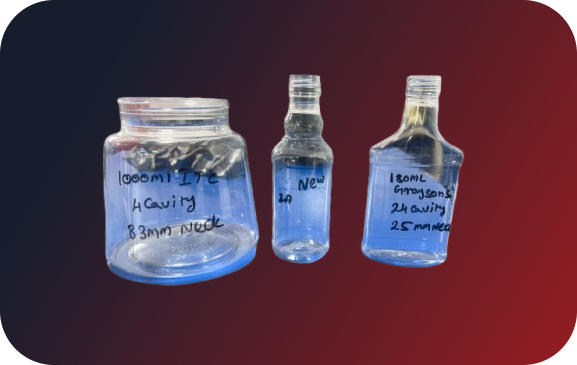

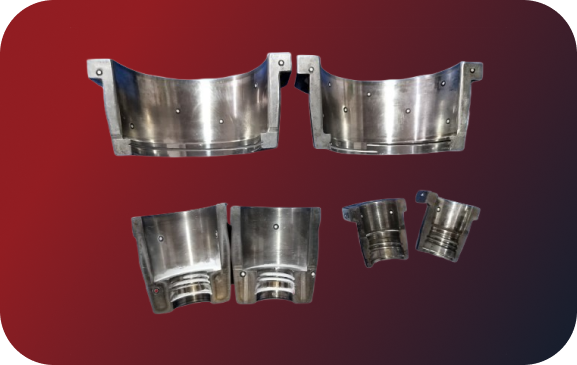

Molds & Die Casting

- Injection Molds – Durable and high-precision molds for plastic injection molding

- Rubber Molds – Custom rubber molding solutions for various industries

Quality Control & Inspection

- Precision Measurement – Advanced inspection tools for dimensional accuracy

- Material Testing – Ensuring durability and performance standards

- Standard operating procedures for in-process and final inspections

Prototyping & Custom Manufacturing

- Rapid Prototyping – Quick development of prototypes for product validation

- Custom Machining – Tailored solutions to meet specific industry needs

Technological Capabilities

- CAD/CAM software for design and toolpath optimization

- Fixture design for VMC, HMC and VTL

- ERP system for job scheduling, inventory management, and traceability

- Digital file transfer and secure data storage for customer designs

Skilled Workforce

- Team of experienced machinists with minimum of 18+ Years in Industry, programmers, and quality control specialists

- Regular training in CNC programming, lean manufacturing, and safety compliance

Logistics & Delivery

- In-house and third-party logistics support for timely delivery

- Established supply chain for raw materials and outsourced processes (e.g., heat treating, anodizing)

We take pride in delivering excellence through precision, reliability and innovation.

Contact us today to discuss how we can support your machining needs!

State-of-the-Art Machinery

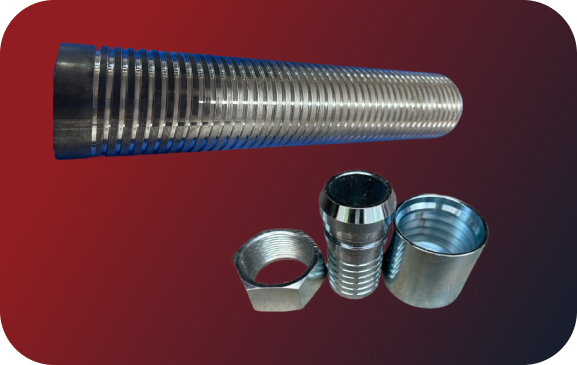

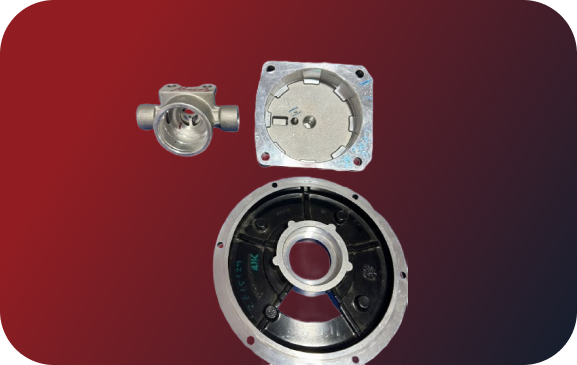

Our Machined Products

Explore our wide range of precision-machined components for various industries

Precision Machining for Modern Industries

At MGT, we offer cutting-edge precision machining solutions designed to meet the demands of modern industries. Our commitment to innovation ensures high efficiency, accuracy, and superior quality standards in every project.

Materials

- Aluminum

- Stainless Steel

- Copper

- Brass

- Plastics

- Ferrous & Non-ferrous metals

Tolerances

Up to ±0.001 mm precision for high-accuracy components.

Equipment

- 2-axis CNC turning centers

- Milling with automated tooling

- CAD/CAM integration

Surface Finishes

- Anodizing

- Powder Coating

- Polishing

- Custom finishing solutions

Non-Destructive Testing (NDT)

Quality checks without damaging components, ensuring reliability and safety.

Reverse Engineering

Recreating and improving existing components with precision and innovation.

Prototype Development

Rapid prototyping to test designs before moving into large-scale production.

With a commitment to precision, innovation, and customer satisfaction, we provide end-to-end machining solutions tailored to your industry's needs.

Diverse Industry Expertise

At MGT, we provide high-precision CNC machining solutions for a wide range of industries. We leverage cutting-edge technology to deliver precision-engineered solutions across industries.

Automotive & Automobile

- Precision-machined components for engines, transmissions, and suspension systems.

- Custom parts for electric and hybrid vehicles.

Aerospace & Defense

- High-precision aerospace components with strict quality standards.

- Parts for aircraft structures, landing gear, and defense applications.

Medical & Healthcare

- Medical-grade machining for surgical instruments and implants.

- Precision components for medical devices and diagnostic equipment.

Electronics & Semiconductor

- High-tolerance parts for circuit boards, enclosures, and semiconductor equipment.

- Custom heat sinks and connectors for electronic applications.

Oil & Gas

- Durable, high-performance components for drilling and extraction equipment.

- Precision-engineered parts for pipelines, valves, and pumps.

Industrial & Automation

- Custom machining for robotics, automation, and industrial machinery.

- Fixtures, jigs, and tooling solutions for efficient manufacturing.

Agriculture & Renewable Energy

- Precision components for solar, wind, and energy storage systems.

- Custom parts for battery technology and energy-efficient solutions.

Quality Assurance & Inspection

Precision measurement equipment

Advanced 3D measurement capabilities for precise quality control and dimensional accuracy verification.

Inspection Tools & Equipment

- Micrometers - Precision measurement tools

- Calipers - Dimensional verification

- Surface finish testers - Quality assessment

Quality Procedures

In-Process Inspections

Standard operating procedures for in-process and final inspections.

Final Inspections

Comprehensive quality checks before delivery to ensure all specifications are met.

Why Choose MGT for Your CNC Machining Needs?

At MGT, we take pride in delivering exceptional precision machining solutions that meet the highest industry standards. Here's what sets us apart:

Cutting-edge CNC Technology

Skilled and Experienced Machinists

Competitive Pricing and Fast Turnaround

Strict Quality Control and ISO-certified Processes

Customer-centric Approach and Tailored Solutions

Technological Capabilities

Ready for Precision Manufacturing?

Get your quote today for high-quality CNC machining services with guaranteed precision and timely delivery.

Contact Us

Address

2/244/8, Kudi Street, 87-Goundampalayam,

Kumaramangalam (PO), Tiruchengode (TK),

Namakkal (DT), Tamil Nadu. Pin-637205.

Phone

Send us a message

We'll get back to you within 24 hours